HTML5 compliant

|

Attention Different browsers interpret web page languages (HTML/ PHP/Javascript/CSS) differently at default. I tuned up this site best for Google Chrome, a most popular browser running on desktops/tablets/ notebooks/mobile phones. Other browsers (Firefox/Edge/IE/ Opera///) might exhibit weird appearance that I do not aim at. |

LSI Products that I was involved in the design

Work categories below are intentionally eliminated from the table as trivial.

(1) Inspection designs at various stages

(2) Customer visit and support

(3) Patents related

(4) Thesis and seminar

(5) Research

(6) Management and presentation

(7) Any other miscellaneous side works

You can make similar tables yourself and recognize what you completed.

People say that "It's easy to say but difficult to do". I say that "It's easy to do but difficult to complete".

(A) NEC, JapanUpdated on

8/28/23

(1) Custom designed LSIs

| LSI Product |

Year | Architecture Specification |

Logic Design |

Firmware Design |

Breadboard Design |

Breadboard Debug |

Logic Conversion |

Computer Simulation |

Mask Layout Design |

System Evaluation |

LSI Test |

| 31 | 1971 | customer | customer | hardwired | customer | customer | 100% | 100% | contractor | 0% | 0% |

| 32 | 1971 | customer | customer | hardwired | customer | customer | 100% | 100% | contractor | 0% | 0% |

| 33 | 1971 | customer | customer | hardwired | customer | customer | 100% | 100% | contractor | 0% | 0% |

| XX | 1971 | customer | customer | hardwired | customer | customer | 100% | 0% | contractor | abandoned | abandoned |

[31, 32, 33]

Mr.Tomoyo Ichikawa of Eiko Business Machine, Inc. designed the original

logic for 8 digits desk-top calculator with Eiko proprietary printer

and divided the entire logic into five LSIs nick-named 31, 32, 33,

34, and 35. Soon after I started working at NEC in June, 1971, I

took charge of 31, 32, and 33 that functioned as Central Processing

Unit, data memory, timing generator, and so forth. I completed the

logic conversion from the original logic schematics given by Eiko

Business Machine to NEC logic modules (blocks) to ease the mask

layout utilizing building blocks scheme as well as the computer

simulation. 34 and 35 were Printer Control Unit and handled by Mr.

Shimizu of NEC. Mr. Shimizu took over system evaluation and LSI test

for all the five LSIs later on.

The computer simulation for LSI was an emerging technology intensively

using main frame at that time. The net list and simulation vectors

were punched on IBM 80 column punch cards line by line.

[XX]

XX was a single-chip 8 digits desk-top calculator LSI designed by Tokyo

Electronic Application Laboratory (President: Hitoshi Kodaira; 東京電子応用技術研究所) based on development request from

NEC. NEC did not have sufficient ability to design desk-top

calculator LSI at that moment. Although I was not a person in charge

of the project, I was requested to complete the logic conversion

because only a limited number of LSI designers was able to do the

work. Because NEC strongly promoted the XX project, a most

experienced contractor was assigned for the mask layout as well.

However, the die size after the actual mask layout had become larger

than 5mm x 5mm due to a lot of internal wire connections derived from

the hard-wired random logic design. At that time, it was common

knowledge that the yield became zero (no good die per silicon wafer)

if the die size became beyond 5mm x 5mm.

At the next stage, I was requested to try to divide the entire logic

into two LSIs (this means that it is not a single-chip LSI). My

conclusion was “Unrealistic and Impossible” because the

number of LSI pins easily went beyond 28 pins due to a lot of

interconnects. The maximum number of LSI pins available was 28 at

that time because of the constraint of LSI packaging technology.

Consequently,

the project XX was eventually abandoned.

Mr. Atsuyoshi Ouchi, a manager of NEC Integrated Circuit division,

decided to pay the compensation for the development to TEAL although NEC did not make anything and any profit from XX. Mr.

Kurokawa, a section manager, applauded the reaction saying “It

is good for future”.

This event triggered two big projects for developing 8 digits single-chip

desk-top calculator LSI (µPD271) and 12 digits multiple-chip desk-top calculator LSI chip-set

(µPD281; program ROM etc., µPD282; Register files + ALU (Arithmetic Logic Unit),

µPD261; Segment decoder, µPD262; Timing counter, µPD264; External memory

register)

to be designed by NEC's own efforts.

Mr. Tomihiro Matsumura, a manager of second circuit technology

department (第二回路技術部), promptly organized the LSI development projects in March,

1972, and held the kick-off meeting. Although I did not know why

this happened, probably unfortunately, I had sat down a seat just in

front of Mr. Matsumura of a square desk for 5 x 6 people (Yamamoto,

Shiraishi, Matsumura, Takashima, Kurokawa vs. Tanaka, Ariga, Takai,

Oguchi, Maehashi, Oura). As soon as I sat down, Mr. Matsumura

immediately started arguing me saying, “Oguchi-kun, although

you may be a rookie......” He disputed my reactions and

resolutions concerning aforementioned XX LSI development. He seemed

not to know the whole course of events that most people sitting there

knew well. I gazed at Mr. Takashima sitting left beside Mr.

Matsumura considering that he tried to evade his responsibility (this

was the first job for him just after appointed to a supervisor.) and

transferred it all to me. Because I believed that I did the best and

the original design had fatal weak point of hard-wired design

approach (Moreover, this is not my own design!), I sat still thinking

that “This is My Way”.

Tomorrow morning, Mr. Takai and Ariga who were actually people in charge of XX

product came to me and told that “Just leave it”. Mr.

Shiraishi, a manager of device design section, also came and told

that “After you left, I clearly defended you with the truth. I

usually say what I want to say.” This was his nature derived

from his origin of Kyusyu island that most Japanese did not have.

(2) NEC originally designed LSIs

(not based upon reverse engineering as well as customer's design)

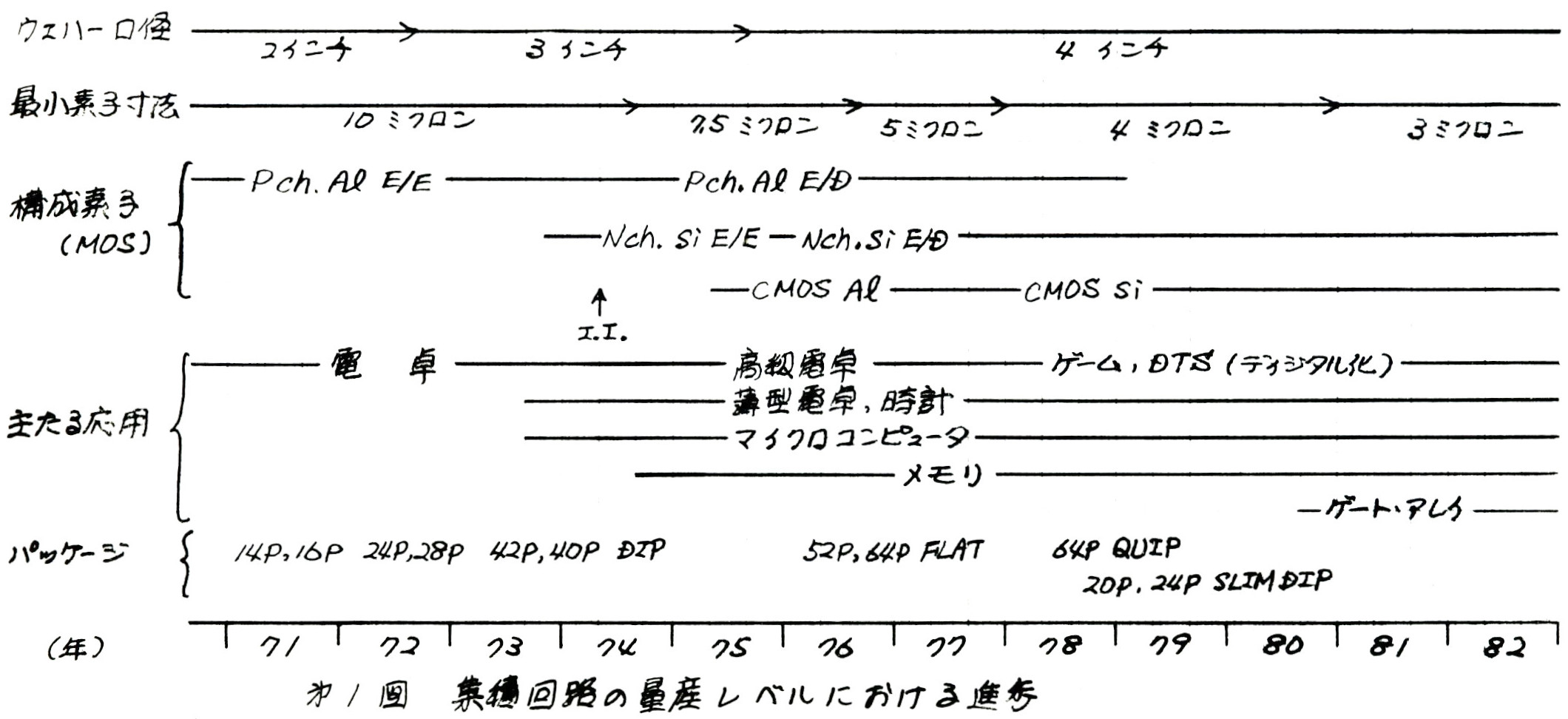

Excerpt from Manuscript of JIEC seminar (page 3)

LSI Device seminar

| LSI Product |

Year | Architecture Specification |

Logic Design |

Firmware Design |

Breadboard Design |

Breadboard Debug |

Computer Simulation |

Mask Layout Design |

System Evaluation |

LSI Test |

| µPD282 | 1972 | 30% | 100% | hardwired | 50% | 10% | 100% | 100%Updated on 10/9/23 |

100% | 100% |

| µPD940 | 1973 | 100% | 100%Updated on 10/16/23 |

50% | 20% | 0% | 100% | 100%Updated on 10/16/23 |

100% | 100% |

| µPD941 | 1974 | derivative | derivative | 100% | derivative | 100% | 100% | derivativeUpdated on 10/9/23 |

100% | 100% |

| µPD942 | 1974 | derivative | derivative | 100% | derivative | 100% | 100% | derivative | 100% | 100% |

| µPD943 | 1974 | derivative | derivative | 100% | derivative | 100% | 100% | derivative | 100% | 100% |

| µPD947 | 1975 | 0% | 0% | 0% | 0% | 0% | 0% | 0%Updated on 10/9/23 |

0% | 100% |

| µPD1201 | 1975Updated on 10/9/23 |

100% | 100%Updated on 10/16/23 |

50% | 0% | 0% | 100% | 100%Updated on 10/16/23 |

100% | 100% |

| µPD1202 | 1975 | derivative | derivative | 100% | derivative | 100% | 100% | derivative | 100% | 100% |

| µPD1203 | 1976 | derivative | derivative | 100% | derivative | 100% | 100% | derivative | 100% | 100% |

| µPD1205 | 1976 | 100% | 100% | 80% | 50% | 100% | 0% | 0% | 0% | 0% |

| µPD777 | 1977Updated on 10/9/23 |

50%Updated on 2/19/24 |

90%Updated on 2/14/24 |

20% | 90%Updated on 9/30/23 |

0% | 0% | 100%Updated on 10/16/23 |

0% | 0% |

| µPD7220Updated on 7/6/23 |

1981 | 100%Updated on 7/6/23 |

100%Updated on 8/21/23 |

hardwired | 100% | 100% | 0% | 5%Updated on 10/9/23 |

100% | 0% |

| µPD7220A | 1983Updated on 9/10/23 |

derivative | 100%Updated on 10/16/23 |

hardwired | 100% | 100% | 0% | 50%Updated on 10/9/23 |

100% | 0%Updated on 10/8/23 |

| µPD72120 | 1987 | 100% | 0% | 0% | 0% | 100% | 0% | 0%Updated on 10/9/23 |

100% | 0% |

[µPD282]

I fully took charge of µPD282, a CPU with memory LSI for 12 digits 1 memory desk-top calculator.

The logic design completed less than one year later I joined NEC in 1971. µPD282 along with µPD281 is the first logic LSI

that NEC originally designed from scratch.

The development project was initiated by powerful direction of Mr.

Tomihiro Matsumura, a department manager, due to the abortion of

single-chip LSI design (XX as mentioned above) for 8 digit calculator

that NEC requested to external independent design house.

I

was so lucky because I was able to build broad LSI design expertise

through the actual µPD282 design in very early stage of my engineering life.

Functions

- 4 x 64 bits (for 12 digits BCD data with one overflow digit + decimal point

BCD data digit + control digit + sign digit) ratio-less shift registers

- 1 x serial BCD full adder/subtractor with carry calculation

- Instruction decoder

- Judge output and ROM code inputs to/from µPD281

- Data & timing outputs to µPD261 segment decoder

- Timing input/output to/from µPD262 digit timing generator

- Data output & input to/from µPD264 extended memory

- Display data outputs to 8 segment fluorescent digit display tubes

Process & Design

10μ P channel metal gate E/E MOS using building block mask

layout, VGG = -24V, VDD = -12V, GND = 0V, Two phase clocks (/φ1, /φ2),

Capacitive dynamic shift registers and transmission gate design

System structure

The 12 digits 1 memory desk-top calculator system consist of a µPD281

(ROM + address sequencer + keyboard decoder; 24 pin ceramic DIP LSI),

a µPD282 (CPU + memory; 28 pin ceramic DIP LSI), a µPD261 (8 segment decoder; 20 pin plastic DIP MSI),

a µPD262 (digit timing generator; 20 pin plastic DIP SSI). µPD264

(extended memory; 20 pin plastic DIP MSI) can be attached to increase

the number of data memories.

Abbreviations

CPU (Central Processing Unit), BCD (Binary-Coded Decimal), ROM (Read-Only Memory), DIP

(Dual-Inline Package), E/E (Enhancement mode for load MOS

transistor/Enhancement mode for gate MOS transistor), MOS (Metal

Oxide Semiconductor), VGG (Voltage supplied to Gate of load MOS

transistor), VDD (Voltage supplied to Drain of load MOS transistor),

GND (Ground voltage), LSI (Large-Scale Integration), MSI

(Medium-Scale Integration), SSI (Small-Scale Integration)

Although everybody expected that the mask-layout of the µPD282

is done by a contractor as usual, I started mask-layout design as

soon as I completed logic design and computer simulation. Mr.

Matsumura came to me and told mischievously with smile, “You

are doing the mask-layout with strong guts, aren't you?”

I experienced work through the night three times for breadboard debug

and x200 stabylen film cut mask base inspection to be done before ordering

physical photo masks.

Mr. Oura taught me how to handle LSI testers, ASR33 teletypewriter, paper

tape, and how to modify the paper tape hole positions by using tape puncher.

update in progress

[µPD940 - µPD943]

update in progress

[µPD1201 - µPD1203]

update in progress

[µPD1205]

update in progress

[µPD777]

update in progress

(B) Chips & Technologies, USA

[82C455 - 82C457]

(C) ASCII of America, USA

[DA7290 - HD814102]

(D) Auctor Corporation, USA

[YY]

(E) SanDisk, USA

[Bishamon] UTF-8 Code MapUpdated on Micrograph Related About Litigation between Western Digital & Toshiba

Excerpt from manuscript of JIEC seminarUpdated on

8/26/23 (page 7)

Application exapmle :

Epoch Cassette VisionCartridge

Epoch Cassette VisionAnatomy

On-chip ROM Dump Related

- System Design of ROM dumpUpdated on

12/16/23

- Dump Pattern Creation

- Dump source pattern (PA.txt)

- Source code of "rom_dump.cpp"

- Dump Analysis

- Source code of "dump_analysis.cpp"

- Dump Result of µPD777 004 Big Sports 12

- Program ROM

- Pattern ROM

- Dump Result of µPD778 Baseball

- Program ROM

- Pattern ROM

- Dump Result of µPD774 Battle Vader

- Program ROM

- Pattern ROM

- Dump Result of µPD777 005 Yosaku

- Program ROM

- Pattern ROM

- Dump Result of µPD777 007 Galaxian

- Program ROM

- Pattern ROM

- Dump Result of µPD777 008 Pakpak Monster

- Program ROM

- Pattern ROM

- Dump Result of µPD777 009 Monster Mansion

- Program ROM

- Pattern ROM

- Dump Result of µPD777 010 Astro Command

- Program ROM

- Pattern ROM

777 to YUV Related

- System Design of 777 to YUVUpdated on

11/6/23

- Video Files

- µPD777 005 Yosaku

- µPD778 Baseball

- µPD777 007 Galaxian

- µPD777 Big Sports 12

- µPD774 Battle Vader

- µPD777 008 Pakpak Monster

- µPD777 009 Monster Mansion

- µPD777 010 Astro Command

NTSC TV Video (RF) Modulator ICs

- NEC µPC626C for µPD777C

(See page 6 of "777 Design Note.pdf")

- NS LM1889 (µPC626C compatible)

[µPD7220 - µPD7220A]

update in progress

[µPD72120]

update in progress

Remarks :

(A) The trial productions were always handled by device design team using photo masks I ordered

to Toppan Printing or Dai Nippon Printing as a result of mask layout design.

(B) LSI testers I used for trial production and evaluation were MH-134 (Minato Tsushinki),

MH-152 (Ando Electric), and MH-200 (Ando Electric).

(1) For wafer check (P/W test), I ordered probe cards based upon pin connection and bonding

pads' position information.

(2) For screening test (選別) and warehousing test (入庫), I ordered DUT (Device Under Test) boards.

(3) For BT (Bias Temperature) test, I ordered BT boards.

(4) For system level test (実装), I made manually-driven system level testers and test programs for

automatic system level testers designed as a result of co-operation

with automation department, later on (applied to µPD282 to µPD1205, 1972 - 1976).

LSI

ProductYear

Architecture

SpecificationLogic

DesignFirmware

DesignBreadboard

DesignBreadboard

DebugComputer

SimulationMask Layout

DesignSystem

EvaluationLSI

Test

82C455

1988

100%Updated on

1/15/24100%

hardwired

none

none

100%

gate array

(Toshiba/

LSI Logic)100%

100%

82C456

1989

100%Updated on

1/15/24100%

hardwired

none

none

100%

gate array

(Toshiba)100%

100%

82C457Updated on

4/22/231990

100%Updated on

1/15/24100%Updated on

11/30/23hardwired

none

none

100%

gate array

(Toshiba)100%Updated on

10/2/22100%

I designed these three IBM VGA compatible flat panel graphics LSIs under joint

development program between ASCII and Chips & Technologies exchanging the

Letter of Intent.

Development historyUpdated on

10/30/23 of 82C455, 82C456, and 82C457

Probing VGA/SVGA/XGAUpdated on

3/4/24 video signals

Gate Array specification

- TC110GUpdated on

10/11/23 Toshiba CMOS Gate Array

Netlist related information

- FRC (Frame Rate Control) Scheme EvaluationUpdated on

11/30/23 8086 Assembly source code

- TC110G MacrocellsUpdated on

11/30/23 Implemented on 82C457

82C457 Application Examples

- DolchUpdated on

12/7/23 Color flat panel portable PC

- AlconUpdated on

12/7/23 Surgical equipment Series 20000

- 82C9001AUpdated on

12/7/23 Data sheet introduces 82C457

Datasheet of companion chips

- 82C460Updated on

9/27/22 Flat Panel Color Palette

- 82C401Updated on

9/26/22 Flat Panel/CRT Clock Synthesizer

- 82C411Updated on

9/26/22 Flat Panel Color Palette/DAC

Flat panel specification (Extracted)

-

Sharp DD (Dual panel Double drive) STN (Super Twisted Nematic) panelUpdated on

10/3/22

-

Sharp 512 Color TFT (Thin Film Transistor) panelUpdated on

10/3/22

US patents applied at Chips & Technologies Inc.

- Go to hereUpdated on

12/11/23. I am ranked as a #4 inventor.

LSI

ProductYear

Architecture

SpecificationLogic

DesignFirmware

DesignBreadboard

DesignBreadboard

DebugComputer

SimulationMask Layout

DesignSystem

EvaluationLSI

Test

DA7290

1993

0%

0%

hardwired

none

none

0%

gate array

(VLSI Technology)100%

gate array

HD814102

1994

2%

2%

hardwired

none

none

0%

gate array

(Hitachi)100%

gate array

- MPEG1 Audio SpecificationUpdated on

11/21/23

MPEG1 audio compression scheme has been using on Movie DVD/Bluray and MP3 (Originaly named from MPEG1 audio Layer 3) audio players.

MPEG skipped MPEG3 and now MPEG4 (MP4; Video and audio compression).

update in progress

LSI

ProductYear

Architecture

SpecificationLogic

DesignFirmware

DesignBreadboard

DesignBreadboard

DebugComputer

SimulationMask Layout

DesignSystem

EvaluationLSI

Test

YY

1996

100%

100%Updated on

11/21/23100%

50%

80%

80%

gate array

abandoned

abandoned

update in progress

LSI

ProductYear

Architecture

SpecificationLogic

DesignFirmware

DesignBreadboard

DesignBreadboard

DebugComputer

SimulationMask Layout

DesignSystem

EvaluationLSI

Test

Bishamon

2000

100%

100%

100%

80%

100%

100%

gate array

abandoned

abandoned

update in progress

Silicon Valley Maps

- 1945 VintageUpdated on

10/6/23

Woodside, Atherton, Menlo Park, Palo Alto, Mountain View, Los Altos, Sunnyvale

- 1975 VintageUpdated on

10/15/23

Mountain View, Los Altos, Sunnyvale, Cupertino, Saratoga, Monte Sereno

- Map ComparisonUpdated on

10/26/23

Evergreen, San Jose, CA (1975 vs. 2023)

- 1981Updated on

10/7/23

- 1982

(Fairchild, NEC Electronics USA, Varian,

Apple, Zilog, NEC America,

Fujitsu Microelectronics, Advanced Micro Devices,

Megatest, Atari, Monolithic Memories, Seeq, LSI Logic,

Dolch, Weitek, Ramtek, IBM, Paul

Masson Cellars,,,)

- 1983Updated on

10/7/23

- 1987

(Chips & Technologies,

Mentor Graphics, Linear Technology, VLSI Technology, Sun Microsystems, Silicon

Graphics, Toshiba America, Intel,

Hewlett Packard,,,)

- 1991

(Oracle, Seagate, Cirrus Logic, KLA, Amdahl, Siemens, Teledyne

Components, National Semiconductor, Televideo, IKOS,

Motorola, Tandem, ACC Micro,

Symantec, Raster Ops, Borland, Xilinx,,,)

- 2001Updated on

10/7/23

- 2005

(Info World, Hitachi, EE Times, SAP,

San Disk, VeriSign, Altera, Texas

Instruments, Yamaichi Electronics, Teradyne, ST Microelectronics,

Sanyo, Infineon, Vishay, nVidia, Mitsui Comtek,

Arm,,,)

- 2013Updated on

10/7/23

- 2018Updated on

10/7/23

Have worked @,

Have visited to

11/20/23

- Die Photo Synthesis by Hugin

- Die Photo Synthesis by Hugin (Scanned Map)Updated on

10/19/23

- Decapsulation of Ceramic DIP

- Decapsulation of Plastic DIP

- Epoxy Removal by Ultrasonic

- Zooming up Die Micrograph on PDF FileUpdated on

8/29/23

I am introducing total 25 die micrographs I made.

When zooming die micrograph using a smart phone or tablet, you possibly experience limited maximum available zoom factor (up to 2x), slow zooming speed, and sometimes freeze because of the factors such as slow CPU, insufficient main memory capacity, and simplified PDF viewer installed.

I recommend using a desk-top PC with large monitor TV (40”), fast CPU (i7), big capacity of main memory (32/16 GB), and fast GPU (8 GB) if possible.

Design

companyManufacturing

companyProduct

NameFunction

NEC

µPD282DUpdated on

10/9/23

12 Digit Desk-top Calculator (ALU, Registers, etc. ) <Tetsuji Oguchi>

µPD941CUpdated on

10/9/23

Single-chip 8 Digit 0 memory Desk-top Calculator <Tetsuji Oguchi>

µPD946CUpdated on

10/9/23

Single-chip 8 Digit 1 memory Desk-top Calculator

µPD1201CUpdated on

10/9/23

Single-chip 12 Digit 1 memory Desk-top Calculator with Printer Control <Tetsuji Oguchi>

µPD777DUpdated on

10/9/23

Single-chip Television Game Processor <Tetsuji Oguchi & Toshio Oura>

µPD777CUpdated on

10/9/23

µPD7220ADUpdated on

10/9/23

Graphics Display Controller (GDC) <Tetsuji Oguchi>

NEC

Intel

iD82720Updated on

10/9/23

Graphics Display Controller (GDC)

- License manufacturing (Second source) of µPD7220

NEC

µPD72120LUpdated on

10/9/23

Advanced Graphics Display Controller (AGDC) <Tetsuji Oguchi, et al.>

µPD765CUpdated on

10/9/23

Floppy Disk Controller {NEC Fuchu Peripheral Equipment Division}

µPD7720ADUpdated on

10/9/23

Signal Processor {NEC Central Research}

µPD277Updated on

10/9/23

Single-chip 8 Digit 1 memory Desk-top Calculator <Toshio Oura>

Casio

NEC

µPD977Updated on

10/9/23

Single-chip 8 Digit 1 memory Desk-top Calculator

µPD871BUpdated on

10/9/23

Digital watch

µPD873GUpdated on

10/9/23

Intel

8080AUpdated on

10/9/23

8 bit Microprocessor

8085AUpdated on

10/9/23

8 bit Microprocessor

iD8086Updated on

10/9/23

16 bit Microprocessor

Intel

NEC

µPD8086DUpdated on

10/9/23

16 bit Microprocessor

- Reverse engineering of iD8086

Oki

80C86AUpdated on

10/9/23

16 bit Microprocessor

- License manufacturing (Second source) of iD8086

Zilog

84C00Updated on

10/9/23

8 bit Microprocessor (Z80)

Nintendo

Ricoh

RP2C02Updated on

10/9/23

Television Game Processor (Family Computer with RP2A03)

Motorola

RP2A03Updated on

10/9/23

8 bit Microprocessor

- Reverse engineering of Motorola 6800

Motorola

68000Updated on

10/9/23

16 bit Microprocessor (Apple Macintosh)

TI

TMS9918AUpdated on

10/9/23

Television Game Processor (Multiple chips)

{}; Architectural design by

<>; Architectural & Logic design by

Enginnering Analysis Report

- SC 179 LSI (Scientific Calculator LSI; 3/4/1974)

- SC 978 LSI (Scientific Calculator LSI; 1/21/1975)

- HP Model 65 (Scientific Calculator with programming function by magnetic tape; 3/10/1975)

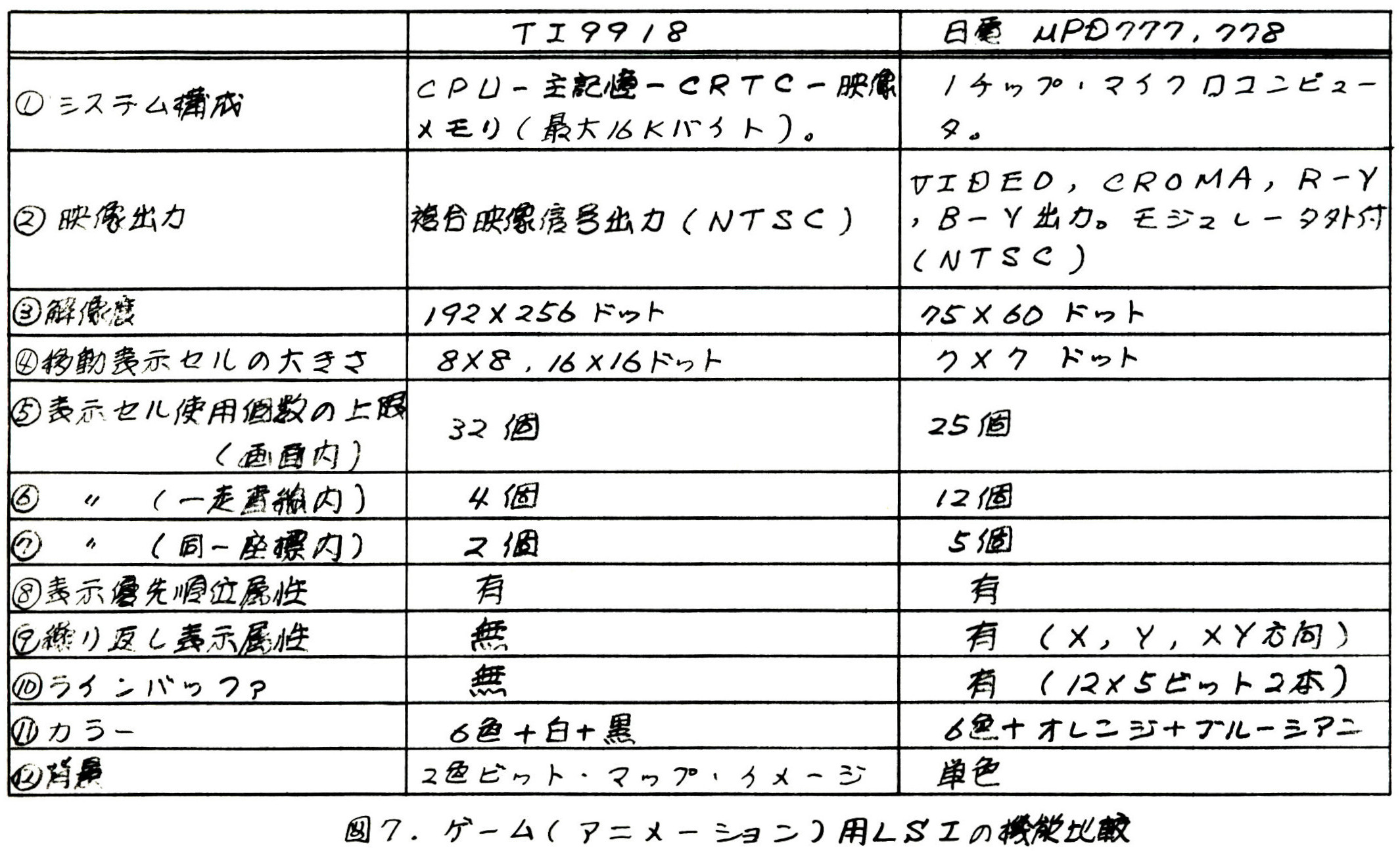

Video Game LSIs

VDP (Video Display Processor) AnalysisUpdated on

7/29/23 (contributed by Mr. Masao Hirasawa, ex-NEC; 9/22/1983)

- NEC

µPD777Updated on

10/9/23 (Epoch Cassette Vision etc.)

- Texas Instrument

TMS9918Updated on

10/9/23 (Sega SC-3000 etc.)

- Ricoh

RP2C02Updated on

10/9/23

(First generation of Nintendo's Family Computer)

Audio Video Processing Related

-

Nvidia Graphics Card InstallationUpdated on

7/28/23

-

Heaven UNIGINEUpdated on

7/19/23 benchmark result

-

Final FantasyUpdated on

7/19/23 benchmark result

-

Topaz Photo AIUpdated on

10/19/23 photo image improvement result

Nintendo's Family Computer (HVC-001)

I have visited Nintendo in 3/1983. It was normal that at least five people

attended when I visited various customers. Therefore, it was so special

for me that only one person attended the meeting held at Nintendo. His name was Mr.

Tsutomu Yamao (Probably, he was involved in HVC-001 development with Mr.

Masayuki Uemura as a deputy manager).

We talked in a room where three arcade game machines were

displayed. After the technical talk completed, he brought us to bigger room

next door filled with

so many arcade game machines. Just before we were leaving, he disclosed that "Nintendo will

release a new game machine for home next month." The product was the epoch-making "Family

Computer".

As soon as it was actually released in 7/1983, he gave me three

Family Computers and six game cartridges with different title.

Over five

years had passed since NEC µPD777/µPD778 (7 bit single-chip microcomputer for

game application adopted by Epoch later on) were released in 1978.

- Family Computer

- Super Mario MusicUpdated on

6/20/23

- Short video of Mr. Masayuki Uemura

FPGA

- FPGA BoardUpdated on

4/5/24

- VGA Color BarsUpdated on

4/3/24

Users Manuals and Design Manuals

- Users Manual NEC µPD7220AUpdated on

9/10/23

- Users Manual NEC µPD72120

- Design Manual NEC µPD7720

- Data Sheet Chips & Technologies 82C455Updated on

9/6/23

- Data Sheet Chips & Technologies 82C456Updated on

9/7/23

- Data Sheet Chips & Technologies 82C457Updated on

10/24/23

Joint Venture of SanDisk and Toshiba

SanDisk acquired by Western Digital and Toshiba

mutually established joint venture concerning NAND flash memory development

& manufacturing at Yokkaichi, Mie, Japan in 2000.

For last 17 years, the two companies have been investing a lot, $XY billion, in proportion to

Toshiba (51%) and SanDisk (49%) beyond five generations of factory

expansion, etc..

As a result of the joint development, San Disk and Toshiba co-authored papers (theses) for prestigious IEEE (Institute of

Electrical and Electronics Engineers) ISSCC (International Solid State

Circuit Conference) and 13 theses were accepted (See “ISSCC

Papers Co-aurthored.pdf”).

SanDisk and Toshiba co-assigned US

patents and 123 patents were registered (See “US

Patents Co-assigned.pdf”).

Western Digital's Concerns

Based upon the long term successful cooperation,

Western Digital expressed help bailing out Toshiba facing with fatal

financial problem (See “WD Willing to Help Toshiba.pdf”),

4/25/2017.

Western Digital CEO Steve Milligan kindly stated concerning

Toshiba problem at WD 2017 third fiscal quarter conference call (Listen to “Milligan

Comment about Toshiba” and read ”Dictation

of Milligan Comment”), 4/27/2017.

Sanjay Mehrotora & Khandker Quader

The joint venture was initiated by Sanjay Mehrotora (Vice president R&D, in

those days) who also requested SanDisk acquisition to Western Digital in

August 2015 as President & CEO of SanDisk.

Khandker Quader led flash memory design cooperating with Toshiba.

The two people already left SanDisk (See “Sanjay

& Khandker.pdf”)

Khandker became President & CEO of SK Hynix

Memory Solutions which is US subsidiary of SK Hynix in June, 2013.

Lawsuit against SK Hynix was filed by SanDisk and

Toshiba in March, 2014 (See “Lawsuit against SK

Hynix.pdf”).

Khandker left SK Hynix Memory Solutions in June,

2014, during the lawsuit.

Sanjay became board member of Western Digital for a while. Then, Sanjay became President & CEO of Micron

Technology in May, 2017.

Micron Technology acquired Lexar Media, one of

competitors of SanDisk flash memory business, in 2006.

Micron Technology fully acquired Elpida Memory,

a Japanese sole DRAM manufacturer merged in NEC (Nippon Electric Company)

and Hitachi, in 2013.

Settlement Announcement

Western Digital CEO Steve Milligan announced the

eventual achievement of the settlement.

(Listen to “Milligan

Announcement about Toshiba” and read ”Dictation

of Milligan Announcement”), 12/12/2017.

My Way of Engineering Life

I keenly feel with the fact that this

song (My Way) exactly expresses my way of engineering life.

My Way

And now, the end is near.

And so I face the final curtain.

My friend, I'll say it clear.

I'll

state my case of which I'm certain.

I've lived a life that's full.

I've traveled each and every highway.

And more, much more than this,

I

did it my way.

Regrets, I've had a few.

But then again, too few to

mention.

I did what I had to do,

And saw it through without exemption.

I planned each charted course.

Each careful step along the byway.

And more, much more than this,

I did it my way.

Yes, there were

times, I'm sure you knew

When I bit off more than I could chew.

But

through it all, when there was doubt,

I ate it up and spit it out.

I

faced it all and I stood tall,

And did it my way.

I've loved, I've

laughed and cried.

I've had my fill, my share of losing.

And now, as

tears subside,

I find it all so amusing.

To think I did all that,

And may I say - not in a shy way?

"Oh no, oh no not me,

I did it my

way".

For what is a man, what has he got?

If not himself, then he

has naught.

To say the things he truly feels,

And not the words of one

who kneels.

The record shows I took the blows,

And did it my way!